Product Description

| Antibacterial Powder Coatings Antibacterial powder coating is a new type of coating with bacteriostatic and bactericidal properties. Because the coating itself is endowed with antimicrobial properties, the growth and reproduction of microorganisms including bacteria, fungi, yeasts, algae and viruses can be kept below the necessary level. Therefore, the products coated with anti-bacterial powder coatings have the function of sanitation and self-cleaning. Applicable to medical and health care equipment, hospital facilities, refrigerators, microwave ovens and other household appliances, commodity display cabinets, steel furniture, mobile phones, telephones, bus or subway handrails, etc. | |||||

| physical property | proportion | 1.2-1.8g/cm3, depending on color and luster | |||

| granularity | The average particle size is 30-38 um, and the proportion of < 64 um particles is more than 99%. If you have any special needs, please ask first. | ||||

| Mobility | It has good fluidization performance and conveying performance. | ||||

| Performance Index of Coating Film | performance | Testing standard | detection result | ||

| Gloss 60 degrees | GB/T9754-88 | 2° to100° | |||

| impact test | ISO6272 | GB/T1723-1993 | 50cm/kg | ||

| Cupping test | ISO1520 | GB/T9753-1988 | ≥6mm | ||

| adhesion | ISO2409 | GB/T9286-1998 | 0 Grade | ||

| Bending test | ISO1519 | GB/T6742-1986 | 2mm | ||

| Pencil hardness | ASTMD3363 | GB/T6739-1996 | >H | ||

| Poached | Distilled water at 96-100 C for 2 hours | No colour, no blister | |||

| Acid and alkali resistance | 5%H2SO4 | GB/T1763-1979 | No colour, no blister | ||

| 48%HCL | |||||

| 5%NaCH | |||||

| 5%NaCI | |||||

| Artificial accelerated aging | ASTM G151 | GB/T1865-2009 | No colour, no blister | ||

| Salt fog resistance | GB1771-91 | 1500H | There was no change in the coating, and the single side corrosion was less than 2 mm at the scratch site. Aluminum chromide plate with 100 um film thickness was used in this experiment. | ||

| Damp heat resistance | GB1740-79 | 1500H | Membrane slightly lost light, < grade 1 | ||

| Construction condition | Curing conditions | It is suggested that 200 C/10 minutes, or 140 C/30 minutes, 160 C/20 minutes and 180 C/15 minutes can be designed according to user's needs. | |||

| Pre-processing | Steel products | Phosphating treatment | |||

| Description: The inspection requirements for pretreatment are checked every two hours, and the test method refers to the requirements of drug suppliers. | |||||

| Spray | This series of products can be applied to the following spraying methods: corona electrostatic spraying; friction electrostatic spraying; electrostatic fluidized bed spraying (requirements first); fluidized bed hot dipping (requirements first); other spraying methodologies (requirements first). | ||||

| Theoretical coverage | Coating thickness: between 40 and 150 microns, the recommended thickness is 50 to 80 microns. Average coverage: 10-12 m2/kg, film thickness 60 microns (calculated by 100% utilization) | ||||

| Other matters | Packaging and transportation | 20kg/box, lined with polyethylene plastic bags, non-hazardous goods, can be transported in various ways, but should avoid direct sunlight, damp and heat, avoid contact with chemical substances. | |||

| Storage requirements | Store in a ventilated, dry and clean room at 30 C. Keep away from fire sources, heating, direct sunlight, and stack in the open air is strictly prohibited. Under these conditions, the powder can be stored stably for 6 months. Over the storage period, it can be re-examined, and if the results meet the requirements, it can still be used. All containers must be re-packaged and returned to the original packaging after use. | ||||

| Health safety | Containers should be kept sealed and not close to fire or heating. Avoid inhaling powder. Food and smoking are prohibited in storage areas. The builder should wear anti-static shoes and keep grounding. Coatings attached to the skin can be washed with soap. | ||||

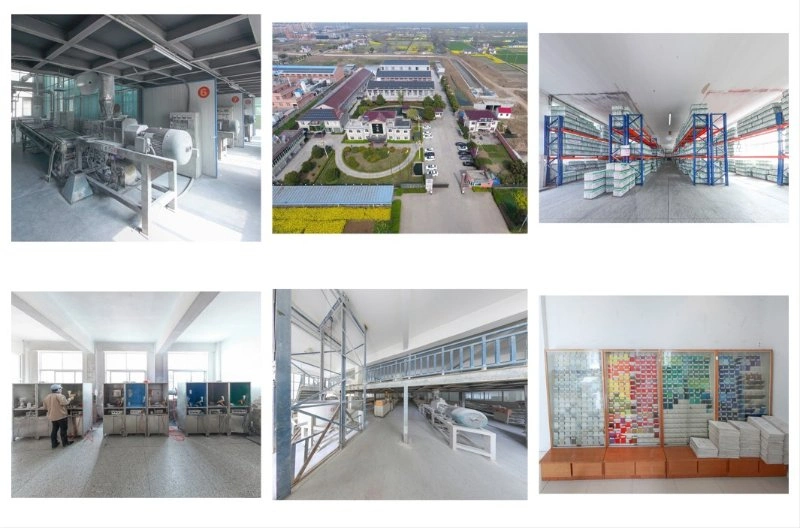

Product process pictures

Company information

| Jiangsu Changsong Technology Development CO., Ltd |

| Business Type:Manufacturer/Factory |

| Year established:1991 |

| Main Markets: Asia Pacific, Middle East, Europe, south & north America |

| Advantage:our factory is close to Shanghai port,convenient transportation;trade assurance supplier; excellent research and development group;professional testing facilities; reliable quality and good service and reasonable price |

Purchase Note:

| 1.M.O.Q : |

| The minimum order is2000kg ,each color ≥ 100kg |

| 2.Colors: |

| RAL color :we usually use RAL colors that is widely used in paint industry and easily find in market |

| Custom color : Color matching is available , if you have colors model ,please send to us for matching . |

| 3.Prices: |

| Prices depend on the colors and using environment ,for prices please tell us the colors and using environment (indoor use or outdoor use). |

| 4.Time of delivery : |

| Production will take about 5-8 days after receipt of prepayment,this is subject to the quantity . |

| 5.Payment : |

| Prefer T/T IN ADVANCE PAYMENT; 30% T/T prepayment , 70% T/T before shipment (or against BL copy) or LC at sight . |

| 6.Samples: |

| 1kg powder sample is available for each color for your testing. |

| Sample is free of cost,but if you pay for the air freight we will highly appreciate. |

Contact us:Eva zhang

Jiangsu Changsong Technology Development Co., Ltd

Mb :+86 18662361801

Website:changsongcoating.en.made-in-china.com